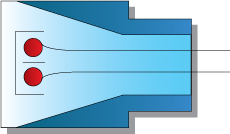

The catalytic detector consists of two small electrically heated beads having a finely divided platinum or palladium coating on the surface. A reference bead ONLY responds to changes in:

- temperature

- pressure

- humidity

The active bead ALSO responds to:

- combustible gases (using the heated catalyst to burn the combustibles)

The two beads are arranged in a bridge circuit such that the heat of combustion on the active bead produces an electrical signal from the increase in its resistance.

In most cases this sensor type has limited usefulness in industrial processes. The catalyst is subject to loss of sensitivity from aging or from poisoning. Lead (organo-metallics), silicones, and halogens can all greatly reduce the catalytic activity of the active bead and reduce the response.

This can happen within just a few hours, even for relatively low concentrations of catalytic poisons. Poison tolerance catalytic sensors resist these effects but even so are not yet suitable for reliable operation under a continuous exposure to catalytic poisons.

- An example: One standard test for poison tolerance is to expose a sensor to 10 PPM HMDS (silicone). The sensor must withstand the exposure for 40 minutes without serious degradation of performance. Older sensor designs can fail after only ten minutes! Poison tolerance sensors however, can last several hours.

While this level of performance may be acceptable for intermittent short-term exposure to poisons, it is not difficult to see that even the poison tolerant sensors are unsuitable for continuous exposure to poisons.

The response time of a catalytic sensor most often depends on the diffusion rate of combustible gas through the flame arrestor. The response time is often specified for a light hydrocarbon gas such as methane, which diffuses quite rapidly. It should be noted that the response time can be two times slower for solvent vapors such as toluol or xylol, which diffuse much more slowly.

Add new comment